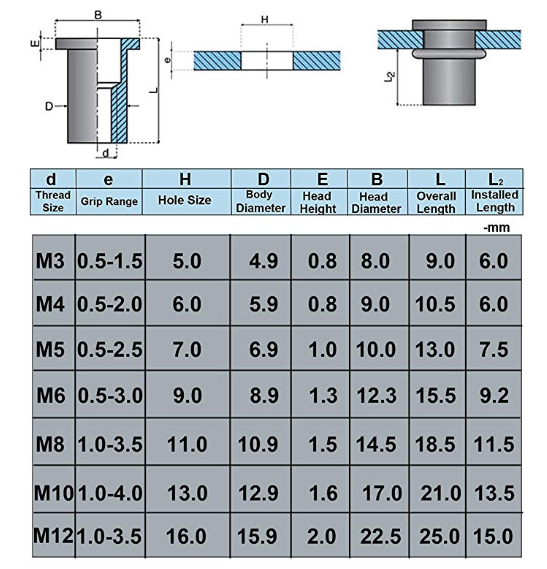

The load applied to a fastener along the joint interface. The recommended thickness range over which the body length will consistently provide a proper setting in a hole of the specified diameter.

(Best practice is to follow the hole size recommendations provided).Īvoid burrs in and around the holes. It may also cause bulging or separation of the members by allowing the rivet to expand between them instead of only on the blind side. Too large a hole will reduce the shear and tensile strengths. Too small a hole will, of course, make rivet insertion difficult. Hole size can be important in blind riveting. These rivets come in many types including standard, multi grip, rainbow (coloured), cup, grooved (Rili), star, Tri-go, Tre-go, mass and hammer.This illustration provides a graphic representation of the POP ® blind rivet selection factors described below. We can also supply Aluminium rivets, zinc plated rivets, cordless riveting tools and hand rivet tools. As a result of these development many future on and offshore projects are expected to propose our closed cup waterproof stainless steel rivet. This is key especially in offshore applications were water ingress can easily lead to crevice corrosion resulting in failure of the system and expensive replacement. The video clearly shows the water seeping through the traditional blind or pop rivet, yet our closed cup rivet remains 100% waterproof with up to 1 metre of water. To show how they compare we have a video that uses the same size of stainless steel rivet produced in the most popular type of blind rivet, these are widely used for metal cladding and jacketing for pipelines and tanks in the oil and gas industry. The CUP sealed blind rivets are made of 316 stainless steel for the body and the mandrel from 318L Duplex and tested to demonstrate 100% waterproof.

#Pop rivet sizes mm free#

HNBR meets the gap left by NBT, EPDM and Neoprene to operate at higher temperatures, resistant to many oils, sour gas and dilute acids with good abrasion resistance it can operate between -30☌ to + 150☌ (-20☏ to + 302☏), Silicon free and UV resistant. They are manufactured from a combination of stainless steel AISI 316 / 1.4401 and Duplex AISI 318 L they also incorporate a unique HNBR washer (gasket). Standard Blind Rivet Sizes:Ĭlosed Cup waterproof stainless steel rivetsĪ long time in testing now released for sale our closed cup stainless steel rivets are the first ones that are 100% waterproof. Order stainless steel rivets for next day delivery in the UK or for courier deliverys around the world Buy Now. The body is deformed when the rivet is set and it is this part, which clamps and holds the materials together securely. The rivet is made of two parts namely, the body (shell) and the mandrel (stem). The materials to be riveted only have to be reached from one side, which explains the term “Blind” riveting. Detailed analysis is carried out of these suppliers to ensure quality is maintained. Products are sourced around the world from suppliers who meet the Group's stringent quality requirements. Our rivets are widely used in oil and gas applications from tanks, vessels, pipework to offshore rigs. We can also supply closed seal rivets for offshore applications and a 100% water tight solution in both duplex stainless and 316 (A4) see below video.

These rivets are sometimes referred to as a “pop” rivet. BS Stainless supply a wide range of stainless steel rivets including 304 (A2) and 316 (A4), the standard dome head blind rivet has a stainless steel body with a steel mandrel (stem), as an alternative they can be supplied all in stainless steel or for specific applications in Duplex or Monel.

0 kommentar(er)

0 kommentar(er)